MOTORSPORT DIAGNOSTICS – BEYOND THE CUTTING EDGE. PART 2

1. CONTROL MODULES.

After discussing the nervous system of a racing car, we need to go through the brain. Unlike humans where you get the reptilian brain for basic functions and the rest of it for all others in a race car each circuit is connected to a specific controller. This is done to avoid failure – compartmentalizing mitigates the risk of failure – if one component fails you should be able to replace it in a matter of seconds.

a. Engine and powertrain management.

When discussing engine management, we also need to include electrical power train vehicles as Formula E and other pure electric and hybrid forms of racing cars are becoming more popular by the hour here. For now, let’s look at the internal combustion engines. In them you must control ignition, air and fuel to create a controlled explosion to generate movement which is transferred to motion with heat as a by-product. Nothing more. The more precise you are the better the performance of the internal combustion engine. Depending on the amounts of strokes each of these cycles can be two, four or six stroke engines which require different timing, ignition, and air. Modern Engine Management Systems use the sensors attached to the engine to measure and calculate the behavior of the engine in each combustion cycle to modify the amount of air going into the combustion chamber, ignition timing and fuel injected. Many racing cars require multiple sets of injectors to be used and so a multiple injection control is also integrated. In motorsports applications you can control anything a regular EDC17/ MED17 can. The Bosch derived ECMs are a very good example because the same company provides both the racing car application and the road car ones.

At this point I think it is fair to discuss the beginning of standalone electronics and their applications for motorsports, this happened back in the 70s in Formula One when the first electronic ignition controls were implemented. Since we are once again talking about history, I must take a brief moment to thank a former colleague of ours, here at Abrites – Ognyan Yanchev who was one of the people who brought standalone ECUs to the masses – he was one of the founders of the Megasquirt project. Ognyan is now retired, but we thank him.

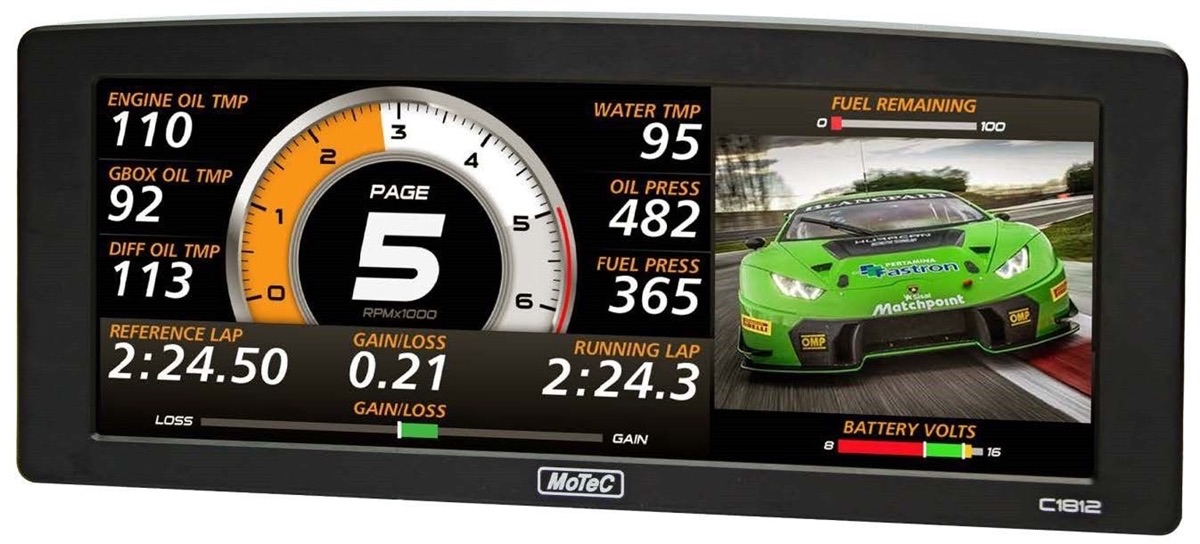

Back to the present. Nowadays motorsport ECUs such as the BIG names in the business: Pectel, Motec, Bosch motorsport currently set the standards not just for engine and powertrain controllers but also for clusters, traction controllers, ABS controllers and many others.

So, a bit more technical information about what makes ECUs in racing cars today so special.

Today motosports ECUs would have the ability to control between 1- and 16-cylinder engines (also between one and 4 rotors if you are a masochist who chose the path of Mr. Wankel), they allow you to run fuel, air and ignition maps up to 20,000 rpm, dual injector controls are also required sometimes as rotaries and even piston engines require it.

• Low- and high-pressure injectors up to 24 in total if you are building a super fancy setup.

• FD CAN support up to 7 or 8 CANs at a time (more about the FD CAN vs regular CAN in the OBD history blog in late July). For management of more separate circles at once.

• The ECUs in modern racecars can refresh much faster than any other ECU in a road car, for example, and have different maps to adjust fuel, boost, and timing on the fly.

• Fuel cut flat shifting is a must when working with sequential gearboxes such as the Drenth , Modena or Hewland units.

• As mentioned above, we have multiple maps because we have different stages of a race, we can expect to see multiple settings for different parts of a competition, for example in a 24h race we can see a qualifying setup with the full potential of the car replaced immediately by a cruise setup to preserve the car’s health for a “night stint”. This is a very typical and a useful feature when talking about endurance racing.

b. Instrument clusters

A typical racecar nowadays has no trace of the old, round Stack or VDO gauges we so dearly loved to see in the olden days of Group B. Today the driver relies heavily on an easy to read, completely configurable dashboard which displays absolutely everything that is going on with the car, these refresh within milliseconds and can display every single aspect from the suspension setup to the tire pressure, boost, fuel consumption, etc.

c. Suspension controllers

Usually a modern racecar is so brilliantly dialed in that your suspension is setup to cope with any part of the upcoming terrain but in many cases (not just offroad racing but track use as well) will require you to make slight adjustments to the suspension, when there are multiple drivers driving the same car it may also boil down to personal preference and the adjustments take moments. Usually these adjustments can be made “on the fly” from inside the car and are preset. These use electric motors to turn a knob or a spring perch to adjust ride height or harden and soften the suspension, adjustable sway bars are commonplace even in road cars, let alone race cars.

d. Steering wheels

If you look at a race car nowadays you will find less buttons on the center console, every possible button has been moved to the steering wheel, fly by wire throttle adjustment, active aero, fuel transfer from one fuel cell to the other, provide the driver with water, even adjust the seating position and lights, mirrors, etc. The philosophy is to move everything towards the driver’s fingertips and not allow excessive distractions.

e. Transmission and traction controllers

Transmission and traction controllers rely on the performance of the engine, like I mentioned before fuel cut flat shifting is a thing and requires a perfect synchronization of the work of both transmission and engine, the shifters are often electro-pneumatic to ensure instant shifting within thousands of a second. Traction control is adjustable throughout the whole race meaning that if the terrain becomes slippery you can adjust the amount of governing you can have. This is controlled via throttle response and braking action as well as action of the differentials to always allow the best traction.

Since all these modules require heavy wiring modern race cars start turning into wi-fi networks to unite all of these and also more complex modules combining multiple other modules within them to minimize the option for failure and reduce complexity while troubleshooting.

2. Differences with electric vehicles

While electric race cars a still few and far between we can see that they are becoming more durable and very much simpler than ICE race cars – there are fewer components and thus there is less to go wrong. The Electric motor is an easier object to control than an ICE, does not require as much complex transmission, the differentials allow for torque vectoring which reduces the traction control requirements. The only problem is that the cars are less endurance oriented and much more of a sprint vehicle because batteries simply cannot hold charge for as long as a fuel driven car.

Both have pros and cons and are hence used for different disciplines which makes motorsport much more interesting to me at least. KERS management is also much easier in an electric car because it requires much less adjustment.

Next week we will talk about the transfer of information and the ability to relay all that is happening on the track to the pits.

Alek

Personalizzazione TCU senza dati FBS4

Personalizzazione TCU senza dati FBS4

Sostituzione BDC2 e Reset Chilometraggio

Sostituzione BDC2 e Reset Chilometraggio